In 1798, French mathematician Gaspard Monge introduced the concept of drafting geometry, which involves using a vertical or horizontal plane to depict three-dimensional objects in two dimensions. This laid the foundation of technical drawings.

Fast forward to the 21st century, where technical drawings have become an integral part of modern engineering.

But why exactly is a technical drawing important? And who uses it? Let’s break it down:

What are Technical Drawings

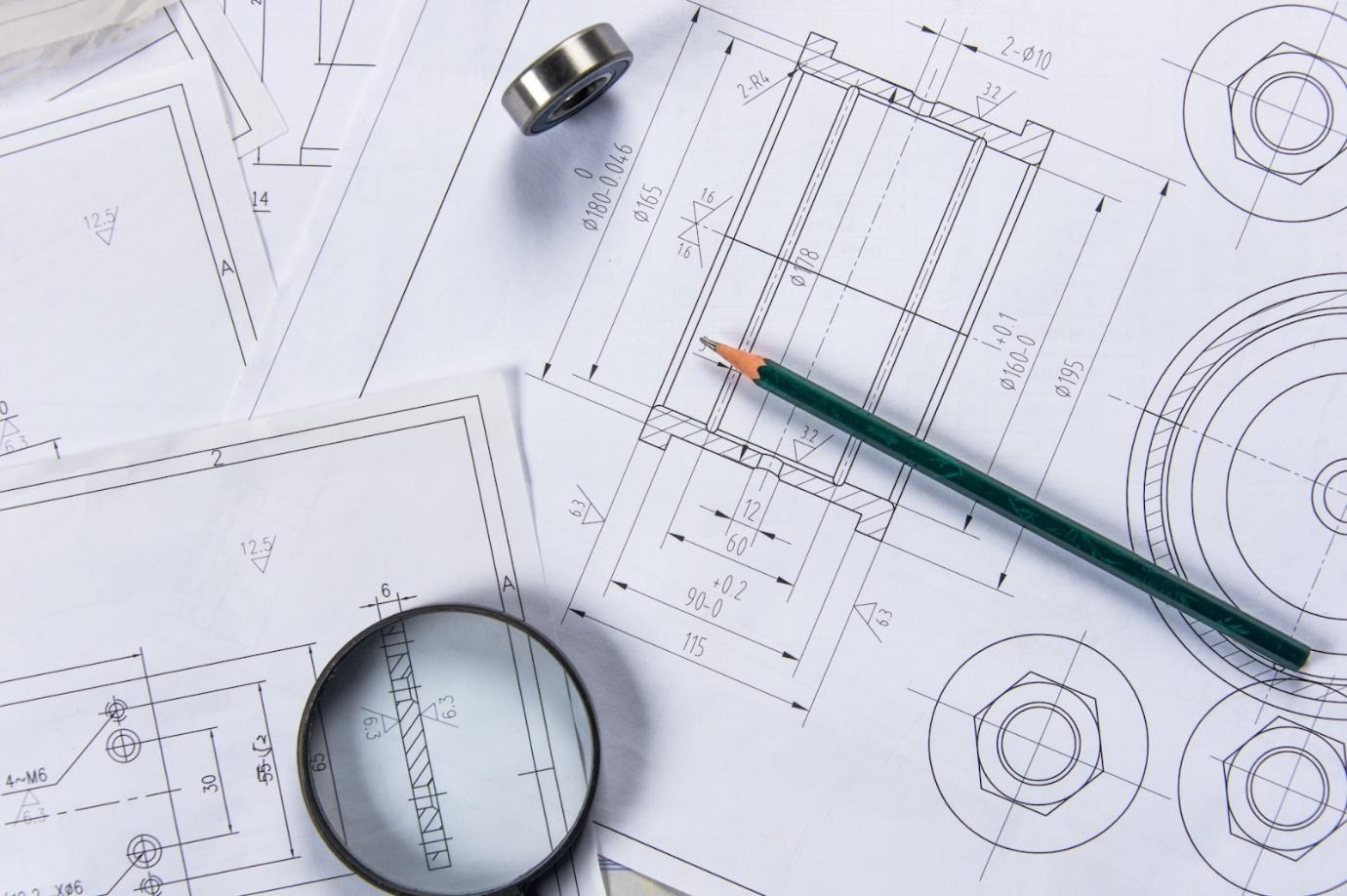

A technical drawing is a detailed, graphic representation of a physical object, structure, or system. Think of it as a universal language for communicating design and manufacturing information, such as shapes, dimensions, and assembly details.

Engineers and manufacturers use predetermined shapes, symbols, letters, and line types to convey technical information. It’s like a secret code between experts.

Some types of technical drawings include:

- Orthographic projection

- Isometric drawing

- Perspective drawing

- Assembly drawing

- Architectural drawing

- Electrical schematic

Technical Drawings in Construction and Engineering

Technical drawings are most widely used in construction and engineering. They are precise and scaled documents, showing how a project should be built or manufactured. Technical drawings turn intricate ideas into visual instructions written in a language universally understood by manufacturers, contractors, and engineers.

Importance of Technical Drawings

Unlike artistic drawings that leave room for interpretation, technical drawings are more structured. Here’s why technical drawings are important:

Clarity and Precision

Technical drawings eliminate guesswork. They show exact measurements, materials, and even methods, removing ambiguity from the process. An unambiguous interpretation ensures precision.

Quality Control

Technical drawings offer detailed specifications, which means each stage of production can be cross-verified. Engineers and constructors can make sure the final product fully complies with the projected design.

Legal Requirement

Technical drawings are often part of contracts. They are binding agreements. If a problem arises, they can serve as evidence.

Minimal Errors

With a technical drawing guiding every step, there is little room for error. Moreover, misinterpretations can be resolved at earlier stages, saving costs.

Interdisciplinary Collaboration

A technical drawing is a valuable tool. It provides the basis for cooperation between design teams, engineers, and contractors. Technical drawings make sure every relevant party is on the same page.

Applications and Industries

In addition to construction, numerous professions and industries rely upon technical drawings (you’d be surprised). Examples include:

- Aerospace engineering

- Automotive design

- Electronics and electrical engineering

The Evolution of Technical Drawings

Technical drawings have come a long way. One of the major breakthroughs occurred during the Industrial Revolution in the 19th century. The invention of mechanical pencils and precision instruments allowed engineers to create highly accurate technical designs.

The 20th century, however, revolutionised this industry. The credit goes to the emergence of computer-aided design (CAD) software. CAD has made design modification and visualisation a breeze. Moreover, programs such as AutoCAD, SolidWorks, CATIA, and Fusion 360 support detailed modeling and testing. The result? Engineers don’t need to create costly physical prototypes.

In the current age, technical drawings are being tested with innovations like 3D modelling and virtual reality (VR). The industry expects innovation and creativity.